SERVICES

GX160 Servicing & upgrade options:

1) Head skim to 2017 regs + valve lap + new head gasket + new valve springs + de-coke the exhaust port + dyno run. This will give more bottom-end performance on track.

2) Block skim to 2016 regs + valve lap + piston rings + hone + new gaskets + break-in oil + dyno run. This will give more bottom-end performance on-track.

3) New ignition coil upgrade, magnet chop to just over 37mm, legality checked & adjusted via the TDC bisect method. This will give more top-end performance and suits fast tracks.

4) Im now updating MSA GX160 engines to the latest V14 regs for 2019 via cutting the valve seats with upper and lower cuts to the existing 45 degree cut.

5) I have an ultrasonic parts cleaner for detailed carb cleaning to a microscopic level of cleanliness, this technique is traditionally used in the medical industry.

6) I have a SportDevices inertia dyno, which can very accurately measure and compare: Power, torque, mean-power and acceleration duration time. It also compensates for all changes in atmospheric conditions. The dyno unit is mounted inside a noise-proof and ventilated dyno box.

With all throttle, brake levers and laptop controls outside the dyno box the for a more low-noise and sociable dyno experience!

7) I have a SuperFlow SF120E air-flow bench, this is a deadly accurate mass-air-flow measuring tool that enables KnighTorque to select the best exhausts and cylinder heads.

8) I have all MSA ABKC gauges for GX160 scrutineer legality checks of cylinder heads, cylinder blocks, piston, carburettor, ignition timing and the camshaft check tool, which has recently allowed me to detect several illegal parts during first service/upgrades.

9) I can help with all forms of tuning, exhaust selection, jetting selection, cam timing, problem diagnosis, precision machining, clutch set-up, engine integration, dyno work and chassis set-up advice.

About My Services:

- All honing equipment and honing procedures are highly specialised, specifically I do not use a 3-leg glaze breaker or a ball-hone which are inappropriate.

- All heads or blocks will be thoroughly checked with ABKC scrutineering gauges and accurately measured before any machining work takes place to ensure legality. All machining work is undertaken by a professional engine machine shop using modern CNC machining equipment and high precision measurement tools.

- Im now updating MSA GX160 engines to the latest V17 regs for 2022.

- Only genuine honda parts will be used, not illegal aftermarket parts.

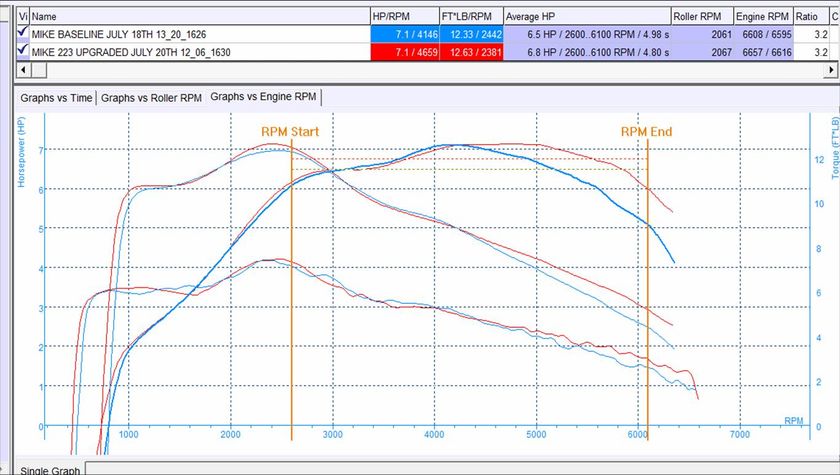

Seen below is a typical example of a dyno carried out by myself;

Average power and acceleration duration is measured from 2600-6100rpm.

Top set of arched lines are before & after power.

Middle set of diagonal lines are before & after torque

Bottom set off diagonal lines are before & after radial acceleration of the dyno flywheel, this helps identify valve surge and to generally help sanity check the torque and power lines.